Embark on a journey to discover the best ERP software for manufacturing, exploring its significance and impact on streamlining operations in the industry. Get ready to delve into the key considerations and integration capabilities that make ERP software a game-changer for manufacturing companies.

Uncover the secrets of customization and tailoring ERP software to meet the unique needs of manufacturing processes, ensuring successful implementation in a plant setting.

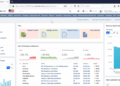

Overview of ERP Software for Manufacturing

ERP software plays a crucial role in the manufacturing industry by integrating various business processes into a centralized system. This technology helps manufacturers streamline operations, improve efficiency, and enhance decision-making.

Key Features of ERP Software for Manufacturing

- Inventory Management: ERP software allows manufacturers to track raw materials, work-in-progress, and finished goods inventory in real-time, ensuring optimal stock levels and reducing wastage.

- Production Planning: With ERP software, manufacturers can create production schedules, allocate resources, and monitor progress to meet customer demands and deadlines effectively.

- Quality Control: ERP systems enable manufacturers to establish quality standards, conduct inspections, and implement corrective actions to maintain product quality and compliance with regulations.

- Supply Chain Management: ERP software helps manufacturers optimize procurement, manage supplier relationships, and track shipments to ensure timely delivery of materials and components.

Streamlining Operations with ERP Software

ERP software streamlines manufacturing operations by providing real-time visibility into various processes, facilitating data-driven decision-making, and automating repetitive tasks. By centralizing information and workflows, ERP systems eliminate silos, reduce manual errors, and improve collaboration across departments. Overall, ERP software enhances efficiency, reduces costs, and enables manufacturers to adapt quickly to changing market conditions.

Key Considerations When Choosing ERP Software

Manufacturing companies have specific needs when selecting ERP software to streamline their operations, improve efficiency, and enhance overall productivity. It is crucial to consider various factors to ensure that the ERP software meets the unique requirements of the manufacturing sector.

Specific Needs of Manufacturing Companies

Manufacturing companies typically require ERP software that can manage complex production processes, handle inventory and supply chain management effectively, provide real-time insights into production schedules, and support regulatory compliance. The software should also integrate seamlessly with existing systems and equipment on the factory floor to minimize disruptions and optimize workflows.

Comparison of ERP Software Options

When choosing ERP software for manufacturing, companies can consider popular options such as SAP S/4HANA, Oracle NetSuite, Microsoft Dynamics 365, and Epicor. Each of these ERP solutions offers unique features and capabilities tailored to the manufacturing industry, such as advanced planning and scheduling, shop floor control, quality management, and analytics for performance tracking.

Scalability Requirements in Manufacturing Settings

Scalability is a crucial factor to consider when selecting ERP software for manufacturing, as companies need a solution that can grow with their business and adapt to changing production needs. The software should be able to handle increased production volumes, accommodate new product lines, and support expansion into new markets without significant disruptions or costly upgrades.

Choosing a scalable ERP solution ensures long-term success and sustainability for manufacturing companies.

Integration Capabilities with Manufacturing Systems

ERP software plays a crucial role in integrating with existing manufacturing systems to streamline operations and improve efficiency. By connecting various departments and processes within a manufacturing facility, ERP software enhances communication and ensures real-time data synchronization between different systems.

Enhanced Communication Between Departments

ERP software enables seamless communication between departments such as production, inventory, procurement, and finance. For example, when a sales order is entered into the system, it automatically triggers the production schedule, updates inventory levels, and generates invoices

Benefits of Real-Time Data Synchronization

Real-time data synchronization between ERP software and manufacturing equipment allows for better decision-making and increased efficiency. For instance, when production data is automatically updated in the ERP system as soon as a machine completes a task, supervisors can quickly identify bottlenecks, track progress, and make adjustments to optimize production schedules.

This real-time visibility into manufacturing operations helps in reducing lead times, minimizing downtime, and improving overall productivity.

Customization and Tailoring ERP Software for Manufacturing

Customization plays a crucial role in the successful implementation of ERP software in the manufacturing industry. It allows companies to adapt the software to their specific needs and processes, leading to increased efficiency and productivity.

Importance of Customization for ERP Software in Manufacturing

- Customization enables companies to align the ERP system with their unique business processes, workflows, and requirements.

- It allows for the integration of industry-specific functionalities that are essential for efficient manufacturing operations.

- By tailoring the ERP software, companies can streamline their operations, reduce redundancy, and eliminate unnecessary steps in the production process.

Insights on Tailoring ERP Software for Manufacturing Processes

- Identify key areas where customization is needed, such as inventory management, production planning, scheduling, and quality control.

- Work closely with ERP vendors to configure the software according to the specific needs of the manufacturing plant.

- Train employees on how to use the customized ERP system effectively to maximize its benefits.

Design Strategies for Successful Implementation of Customized ERP Software

- Establish clear objectives and goals for the customization process to ensure alignment with business objectives.

- Involve key stakeholders in the design and implementation of the customized ERP software to gain buy-in and support.

- Monitor and evaluate the performance of the customized ERP system regularly to identify areas for improvement and optimization.

Conclusion

In conclusion, the best ERP software for manufacturing offers unparalleled efficiency and optimization for companies in the industry. With its integration capabilities, customization options, and seamless operations, ERP software stands as a vital tool for success in the manufacturing sector.

Essential FAQs

How important is ERP software for manufacturing?

ERP software is crucial for manufacturing as it helps streamline operations, enhance communication, and improve efficiency.

What are the key features of ERP software ideal for manufacturing?

Key features include inventory management, production planning, supply chain optimization, and real-time data synchronization.

How can ERP software be tailored for specific manufacturing processes?

ERP software can be customized by integrating specific modules, workflows, and reporting tools tailored to the unique needs of a manufacturing plant.

What are the benefits of real-time data synchronization between ERP software and manufacturing equipment?

Real-time data synchronization ensures accurate information flow, improved decision-making, and enhanced production efficiency in a manufacturing environment.